The temperature transmitter controls all communication between the temperature measuring point and the control room to ensure the accuracy and safety of the communication. The temperature transmitter recognizes the status of the terminal through the change of resistance. Before the wrong value is used, and some wrong measurement points cause a crash, it will feed back to the control room to ensure that the transmitter is always more safe and accurate.

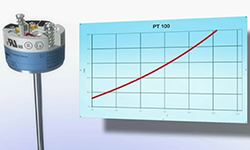

| Due to the additional AD and DA conversion, it is more accurate to use a temperature transmitter than directly connected to the temperature sensor, because the direct connection leads to a much larger total analog error. This is due to the PT100 two-wire or three-wire connection enlarge error. For example to the error of the thermocouple measurement, such as the bigger thermoelectric potential at the transmission point, the plug, and even the compensation wire. |

| Latest design transmitters can configure and support all commonly used thermal resistances and thermocouples. Curve tables of all sensor types are stored in the transmitter, so the highest possible accuracy can be achieved. In addition, the accuracy of the complete measurement chain can be improved by using a specific sensor transmitter matching function. |

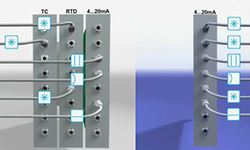

| The temperature measuring point no longer needs special treatment and can be easily connected to the system. The transmitter can use standard 4-20mA boards, Hart, Profibus, or FF protocol for communication. These input boards replace part of all temperature input boards that need to be connected directly, so that the budget and maintenance of the measurement and control system will be more economical, because all spare parts are standard, with greater flexibility in use, resulting in lower inventory costs, and even the entire engineering design process becomes simpler, faster and economical. |

| The temperature transmitter can also better protect and reduce the threat of measurement failure, and the electrical isolation function of the transmitter can avoid ground loops. The advanced diagnostic function can also get information about the status of the measuring point, such as sensor damage and open circuit; to help users operate and maintain the system, even without special understanding of sensor technology, and no need to be a temperature technical expert. This is why the use of transmitters can achieve SIL2 standards, while direct wiring cannot. |